New Use of Poly-L-lactic Acid as Shape Memory Material

New Use of Poly-L-lactic Acid as Shape Memory Material

Background technique

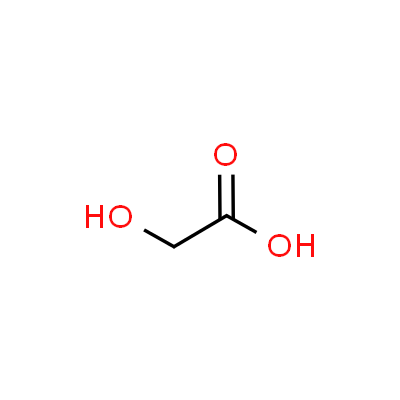

Biopolymer is an important medical polymer material with good biodischarge and bioabsorbability advantages. It has been widely used in outdoor fixation, tissue engineering stents, operation lines, drug control, etc. Polylactic acid is usually synthesized by the ring polymerization method of lactide. According to the difference of optical ring-opening polymerization, the lactide properties are divided into D-lactide properties, L-lactide properties and DL-lactide properties. The product of its ring-opening polymerization Corresponding to poly D-lactic acid, poly L-lactic acid and poly DL-lactic acid. Through literature search, it is found that D-lactide and L-lactide are characterized by ring-opening polymerization at a molar ratio of 1:1 to obtain poly D, L-lactic acid emulsion, and polylactic acid synthesized from DL-lactide has shape memory. However, there is no report on the shape memory properties of PLA in the existing literature.

Summary of the invention

Due to the discovery of the shape memory properties of poly-L-lactic acid, the purpose of the present invention is to use this shape memory property to provide a new use of poly-L-lactic acid as a shape memory material. It is formed into two initial shapes at a temperature of ℃ and a polymerization pressure of -10 MPa to obtain L-lactic acid with the characteristics of memory shape, and the obtained poly-L-lactic acid is used in experimental medicine to discover memory polymer materials. After L-lactic acid is deformed below 100°C, the deformation recovery temperature can reach 100°C. Therefore, polylactic acid has shape memory characteristics below 100°C, that is, polylactic acid with shape memory characteristics and biodegradability is used for medical purposes. Material, other advantages of other materials: because polylactic acid has the memory characteristics of shape memory, it can return to the required shape by heating in situ, and the wound can be restored in this way, which is painless for new patients; poly L- Lactic acid is biodegradable, it can be degraded into toxic products in the human body, so that the material can avoid the long-term adverse reactions and reactions caused by atypical materials in the body, and it can also be used for non-optimized materials. In some cases, a second operation is required. The pain caused to patients; at the same time, polylactic acid has a good biodiversity within the scope of adjusting its various properties to adapt to different medical needs, which is unmatched by traditional medical shape memory alloys; in addition, L -Lactic acid has better mechanical properties and slower speed than polylactic acid polymerization, and it is more preferred as a fixed material. Compared with the existing biodegradable bio-memory polymer, poly-L-lactic acid has extremely rich mechanical properties, which is ground-breaking for internal fixation and application fields. When in use, the shaping and deformation process is as follows: when it has been heated to temperature deformation, when it is heated to temperature deformation (the temperature is lower than the glass transition temperature is 0 ℃), at this time, the phase changes, and the second change under the action of external force. Shape; under the action of maintaining high temperature, the poly, L-low temperature state is cooled to vitrification, becoming vitrified, the molecular chain is melted, and the poly L-lactic acid elastically forms a stable solid shape after deformation; when there is a second type When the shaped poly-L-lactic acid is heated to the shape recovery temperature (at Tf temperature, below 100°C), the phases converge again, and the L-lactic acid returns to the initial stage of the shape memorized by the phase. The mentioned deformation methods can be diameter expansion, stretching, compression, bending, any one or a mixture of several.

Poly-L-lactic acid is about through the ring-opening polymerization reaction and other electrolyte copolymerization to form polymer, the copolymer of poly-L-lactic acid is mainly the fluid of L-lactide and other lactide, L-lactide and nature lactone And the parameters of L-lactate and impurities section. The kinetic speed of the polyDL-catalyst is faster than that of the poly-L-catalyst, and its kinetic performance can actually be adjusted; the glass transition temperature of the polyglycolate characteristic is lower than that of the poly-L-lactic acid, about 45℃. The glass transition temperature of the lactone is lowered, about -60°C, among which poly-L-polylactic acid is copolymerized with any one or the three copolymers within a wide range, and its shape recovery temperature can be adjusted and various physical and mechanical properties can be adjusted at the same time. And dynamic performance. Blends to adjust its shape recovery as well as mechanical properties and optimize applications to more refined biomedicine. The polylactic acid composite material, in which annual apatite is the main component of natural bone, has excellent biological activity and bone properties, and can form a direct bony bond with bone tissue. Therefore, the poly-L-lactic acid memory containing HA particles Polymers have great application potential in bone properties.

Polylactic acid (PLA) uses polylactic acid (PLA) as raw material, is fermented and extracted through fermentation, and then undergoes exquisite oligomerization, high temperature, and polymerization. PLA is biodegradable. It can be completely degraded by microorganisms in the soil within one year after being discarded to produce CO2 and water. The chemical book does not pollute the environment. PLA makes aliphatic polymers. It has the basic characteristics of general polymer materials, good mechanical processing properties, and low shrinkage. It can be used for most synthetic plastics. It is widely used in packaging materials, earphones, home appliance housings, and fibers. , 3D consumables, etc.

Biopolymer is an important medical polymer material with good biodischarge and bioabsorbability advantages. It has been widely used in outdoor fixation, tissue engineering stents, operation lines, drug control, etc. Polylactic acid is usually synthesized by the ring polymerization method of lactide. According to the difference of optical ring-opening polymerization, the lactide properties are divided into D-lactide properties, L-lactide properties and DL-lactide properties. The product of its ring-opening polymerization Corresponding to poly D-lactic acid, poly L-lactic acid and poly DL-lactic acid. Through literature search, it is found that D-lactide and L-lactide are characterized by ring-opening polymerization at a molar ratio of 1:1 to obtain poly D, L-lactic acid emulsion, and polylactic acid synthesized from DL-lactide has shape memory. However, there is no report on the shape memory properties of PLA in the existing literature.